Navigation

PICS introduction

Product interconnection system (PICS)

With the demand for more complicated metrology systems, the amount of information that must be transferred to and from the co-ordinate measuring machine (CMM) continues to increase. To simplify this information transfer, PICS has been developed to standardise the real time communications format for Renishaw's products.

This document describes the PICS connection between the Renishaw interface and the CMM controller, with the exception of the 'Types of input signal' and 'Cable connection' sections which briefly describe the PICS input connection to a Renishaw interface.

Standardisation allows products, such as the Renishaw motorised head system and the autochange system, to communicate with both the probe interfaces and CMM controllers.

Due to the nature of various real time signals incorporated in PICS, extra protection is afforded to precision metrology components.

System overview

PICS can be incorporated in a range of systems of varying complexity. Four examples are shown in the following figures.

NOTE:

- The order in which the elements of the system are connected is important

- The system must have an external interface to operate correctly

- If used, the motorised head controller should be furthest from the CMM controller

- If used, the autochange system should be the closest to the CMM controller (except for installations containing a PI 800-2 interface)

- All PICS connectors to Renishaw equipment are 9 way ‘D' type plugs and sockets

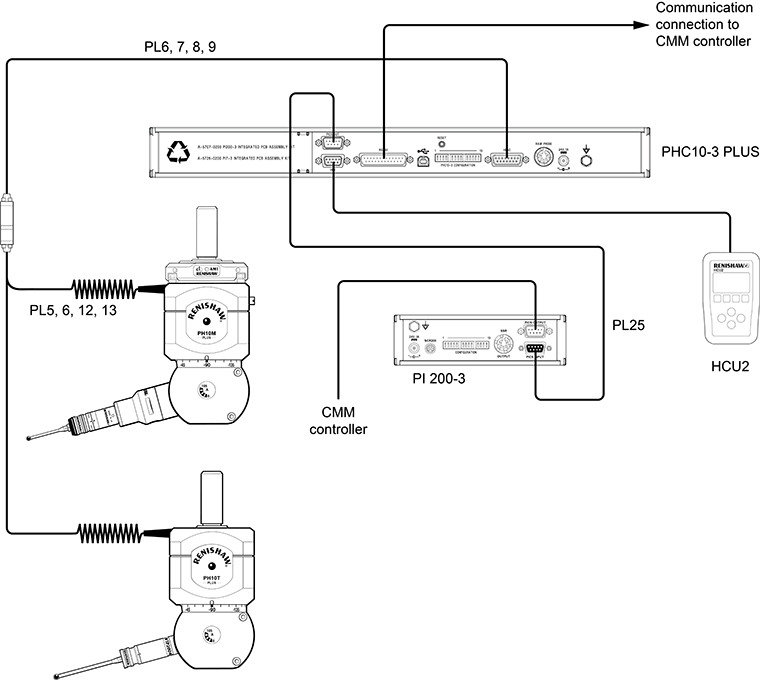

PHC10-3 PLUS and PI 200-3

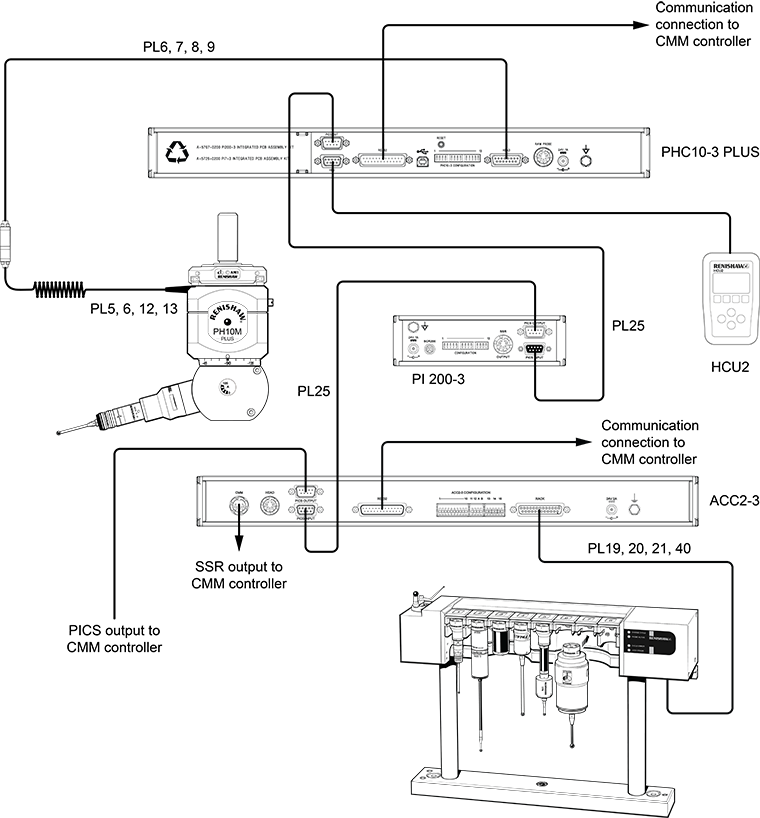

PHC10-3 PLUS and PI 200-3 with autochange

PHC10-3 PLUS and PI 7-3

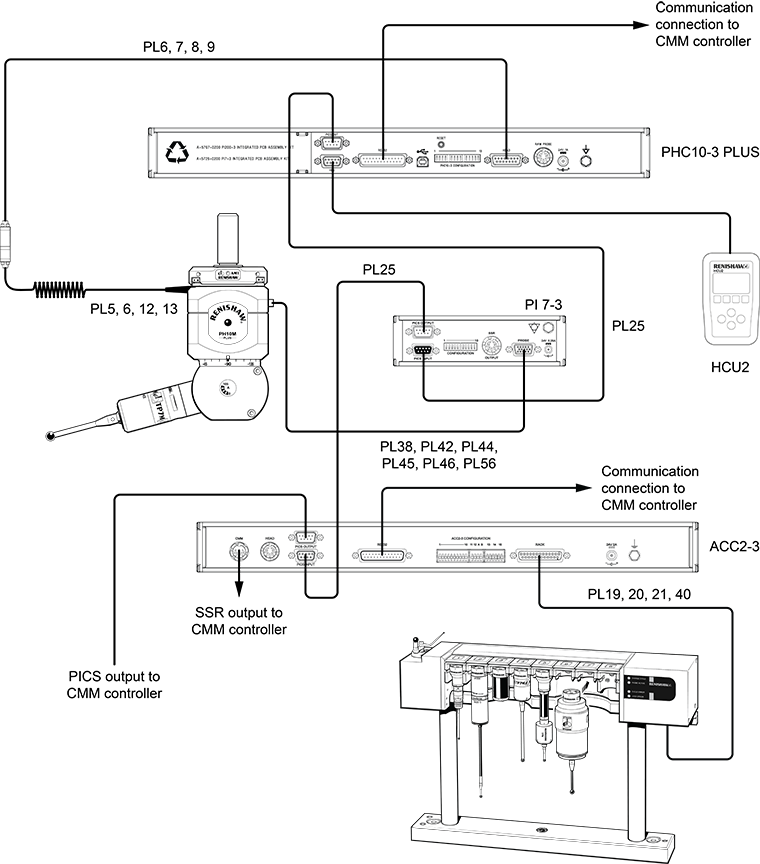

PHC10-3 PLUS and PI 7-3 with autochange